University of Virginia Heating Plant Hot Well Replacement

The University of Virginia's (UVA) main heating plant in Charlottesville is vital for campus steam services, with a critical component being the hot well for condensate return. Hot well failure risks heating plant shutdown, steam supply disruption, boiler damage, and critical facility closure. Over time, a water leak leached the chlorides out of the cement in the surrounding concrete of the original hot well, corroding 304 stainless steel components.

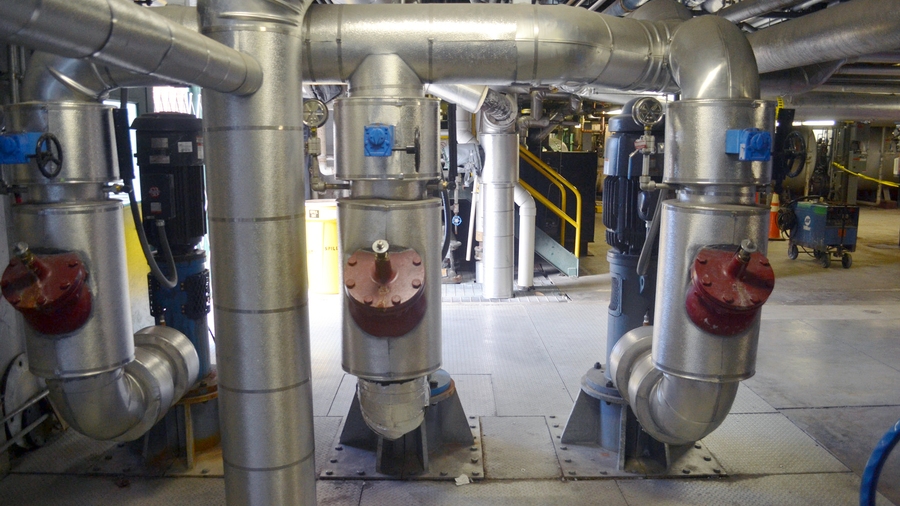

CHA was responsible for emergency design and construction administration to configure a temporary bypass system that prevented any interruption to the UVA Hospital and connected academic, research, and administration buildings. With the campus distribution system operating, the original hot well was demolished, and the replacement hot well was fabricated on-site using 316 stainless steel. The new design included enhanced provisions for convenient servicing, maintenance, and inspection. The transition to the new hot well was seamless, without service disruption. UVA Hospital and other structures functioned without interruption and the temporary bypass remains for redundancy, increasing system reliability.

Project summary

Over 550 buildings on the UVA campus, including a Level I trauma center.

Zero minutes of service disruption.

One temporary bypass remaining for redundancy.

Talk to an expert

Jim Fuller, PE, LEED AP*

Senior Vice President,

Power Delivery & Integration Business Line Director

Jim has over 30 years of experience with a focus in the design and management of electrical projects. He has designed electrical systems for utility, renewable generation, transportation, industrial, municipal, commercial, and institutional facilities.